+8613251068920

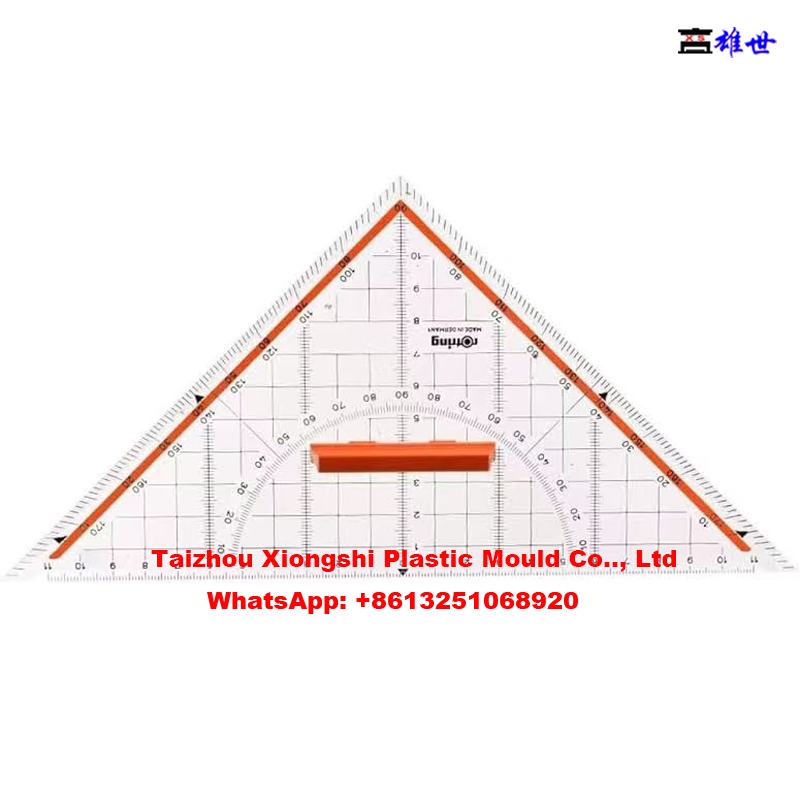

+8613251068920Injection Molding for Rulers - High Quality Ruler Mold and Measuring Scale Mould Supplier. This is acrylic ruler mold.

I. Ruler mould part design.

According customer's request, ruler design copy from original samples from the market.

We scan the samples and input the data into computer and then use UG software to complete the part 3D design.

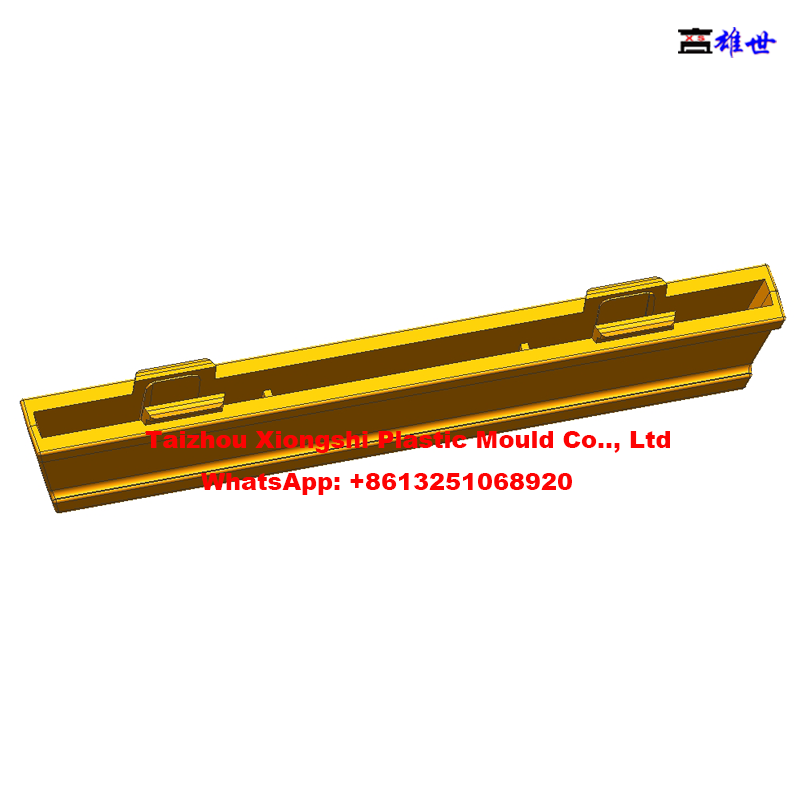

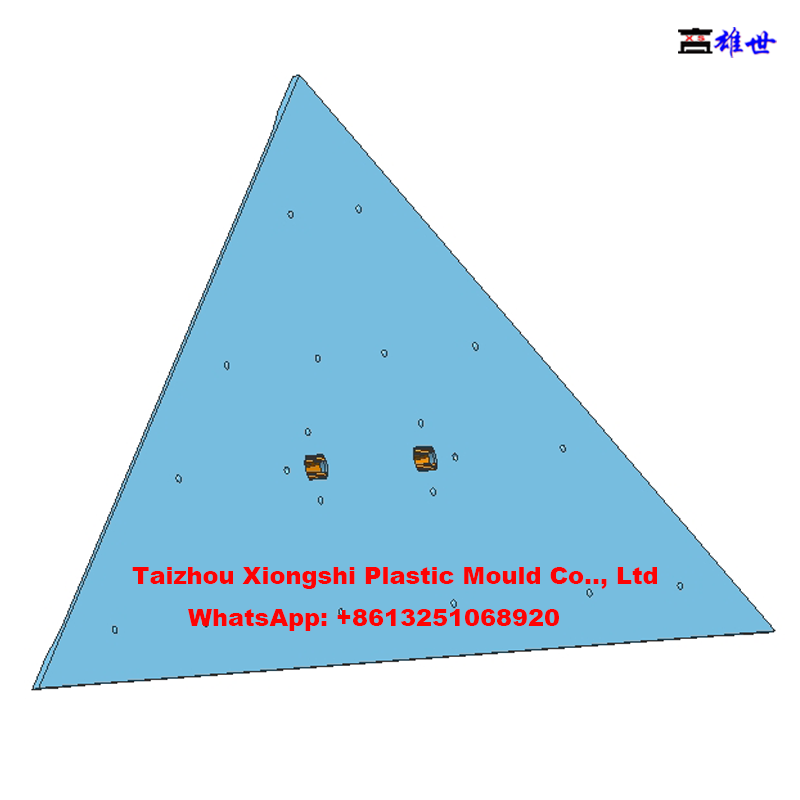

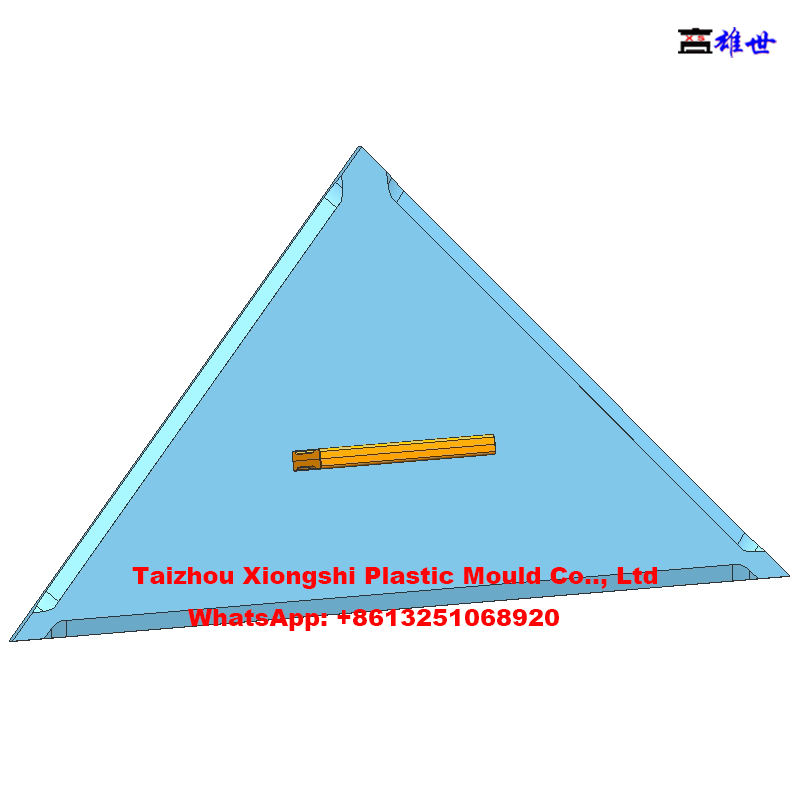

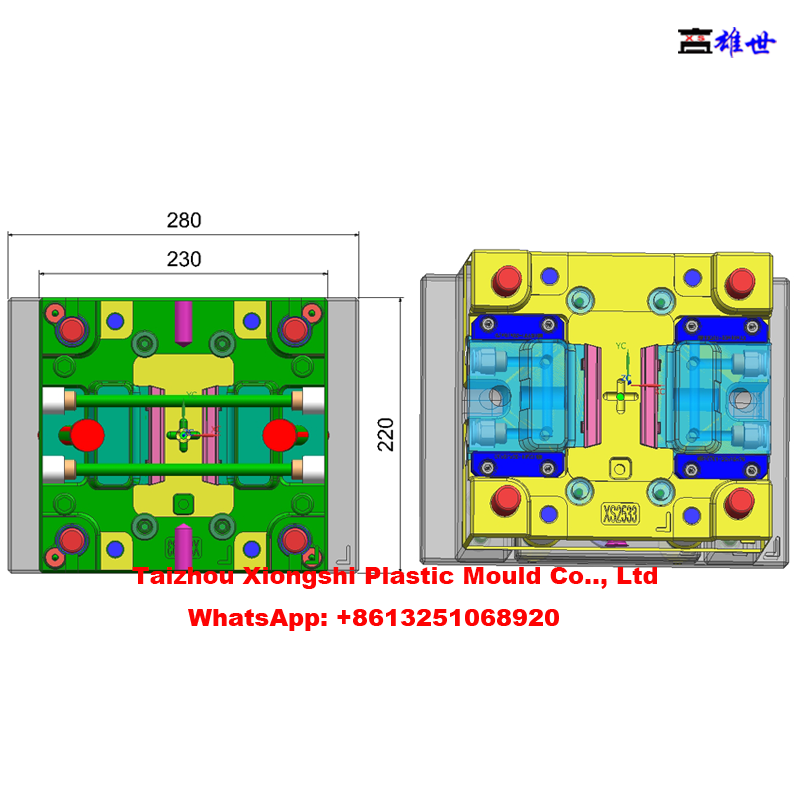

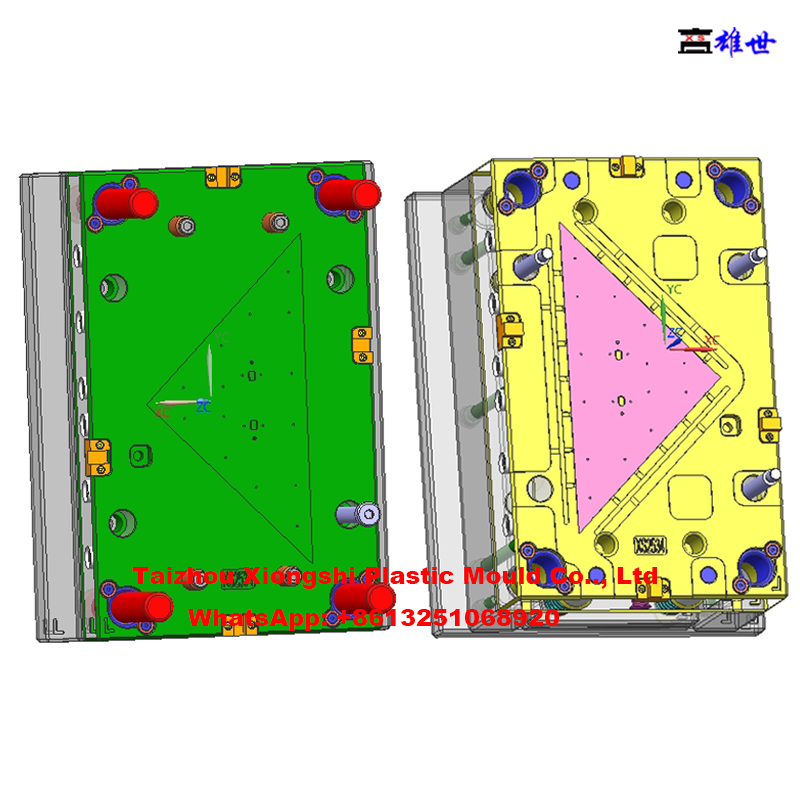

II. Ruler mould 3D design.

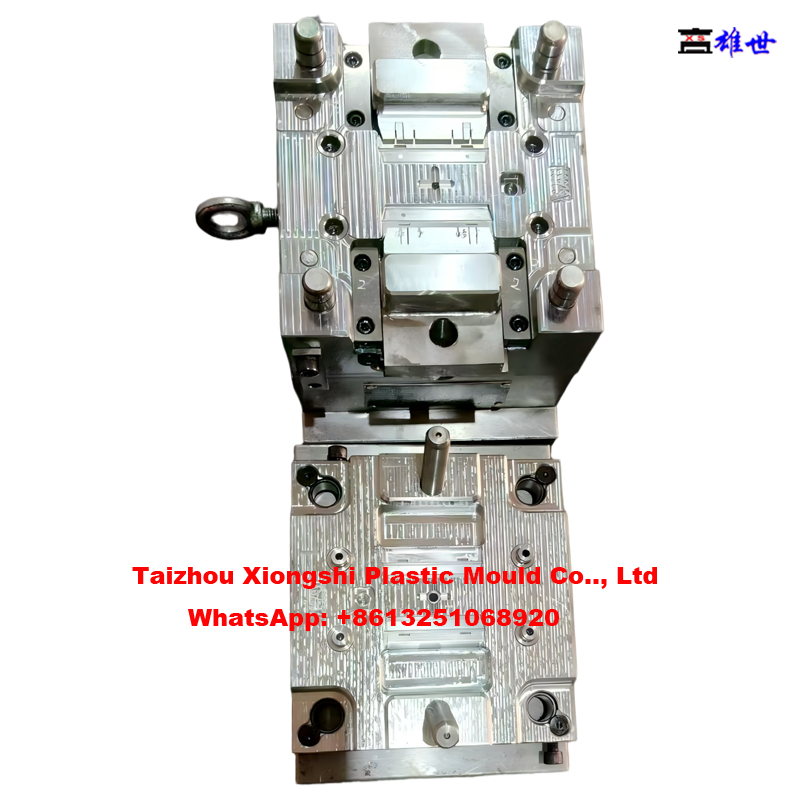

Due to customer's injection machine is very small, so ruler mould was made 1 cavity and ruler small part made 2 cavities. Due to this product design simple and there is original samples can check the gate position and sizes, so there is no necessary to do the DFM analysis and MoldFlow analysis.

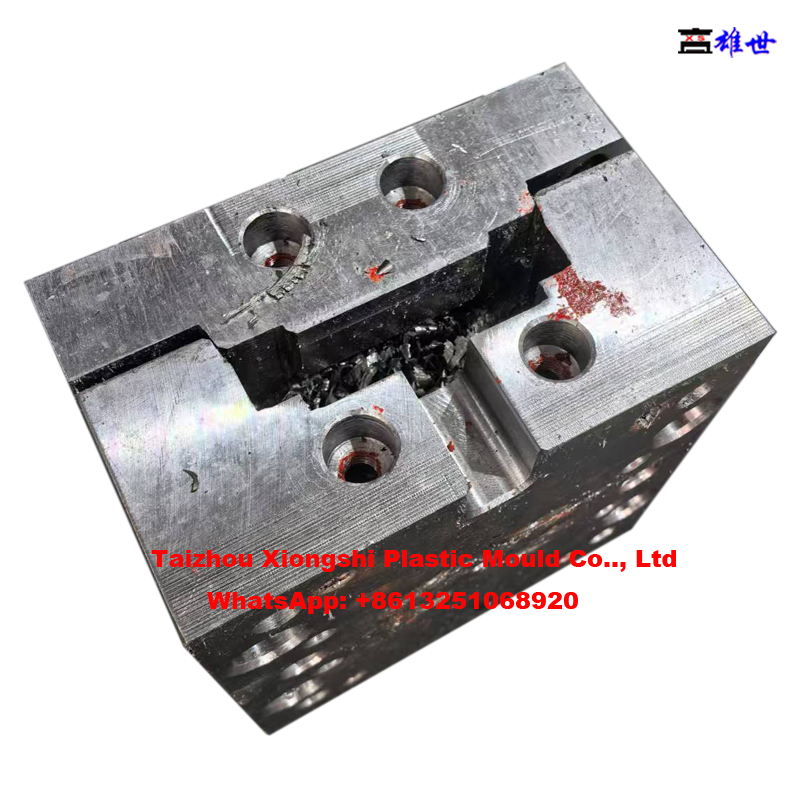

III. Ruler mould machining.

As commodity mould, ruler mould machining mainly need CNC milling tooling, CNC engraving tooling, hole drilling, deep hole drilling, gloss polish, etc. All of them are normal tooling process.

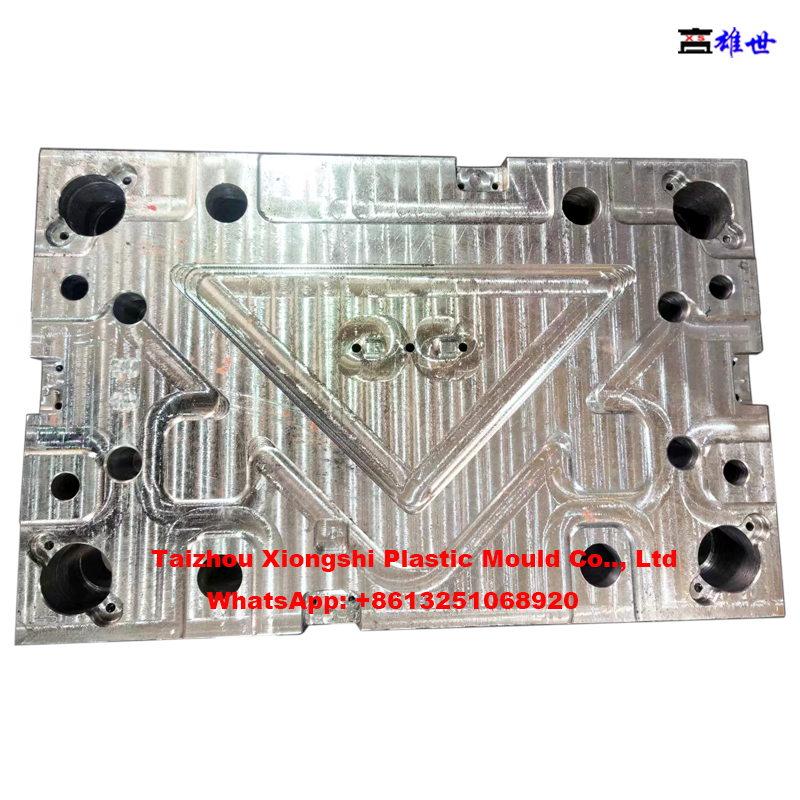

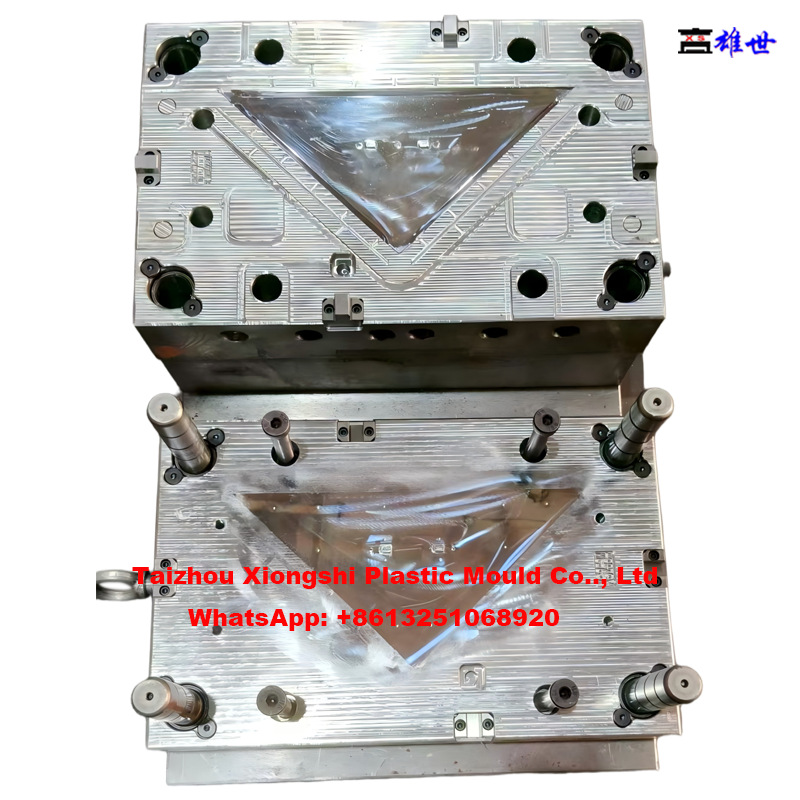

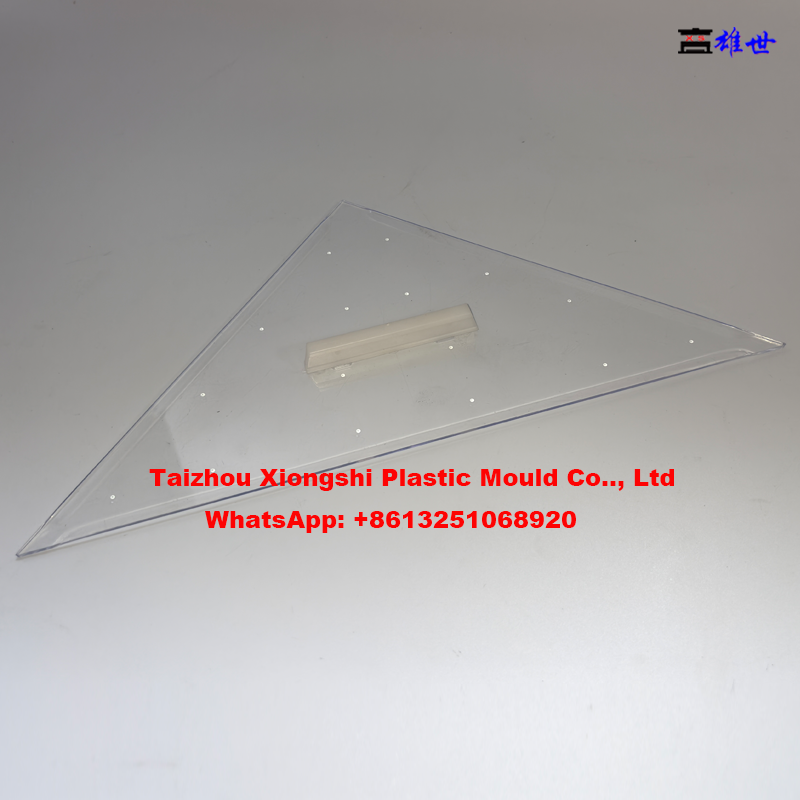

IV. Ruler mould pictures.

Most of countries custom require the products pictures for the custom clearance. So we will take the moulds pictures like this for each mould before delivery.

V. Ruler mould test.

All the moulds test with our cost. Only when customer have special request, such as, test moulds with more than 100 shots, running moulds more than 2 hours, etc. Which the cost much higher than normal mould test needed, then we will send the extra bill to client.

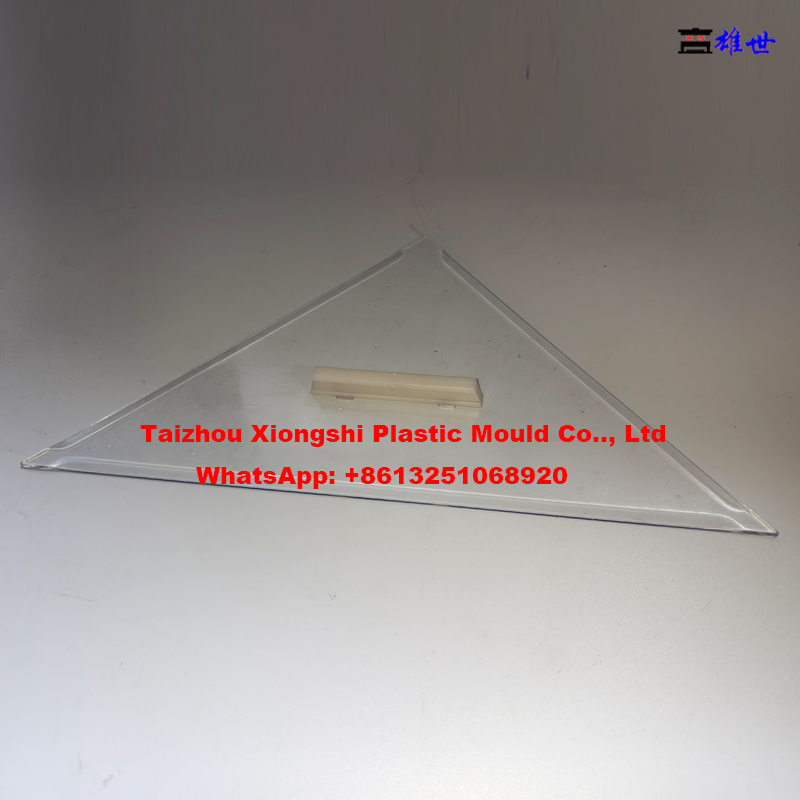

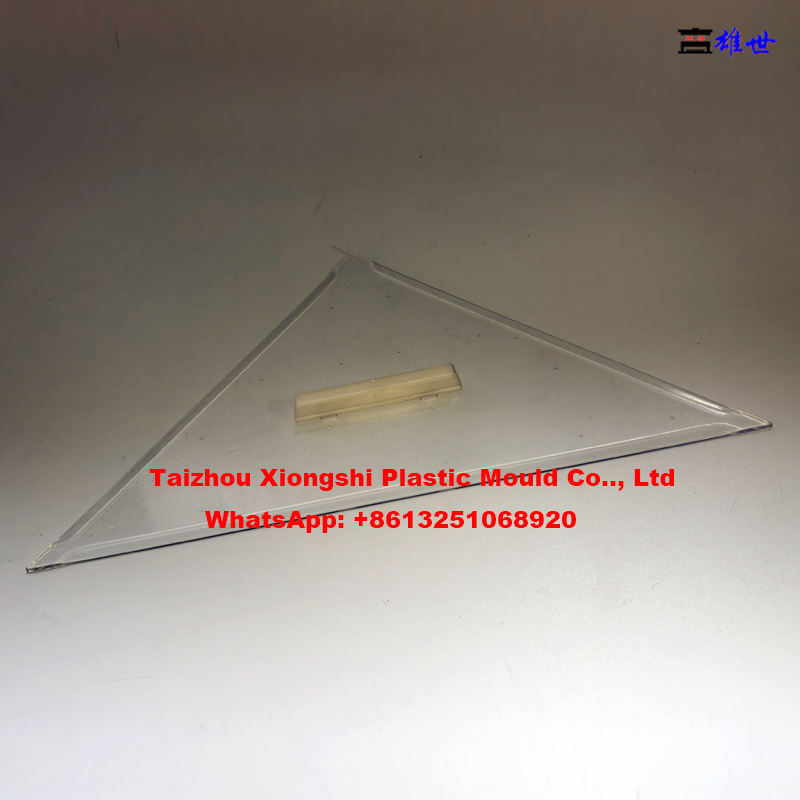

VI. Ruler mould test samples.

Mould test samples use the same new plastic material of the original samples. Or use the same plastic as per customer's request during mould design stage. This ruler main part made by PS material. And the small part made by HIPS material.

VII. Ruler mould delivery.

The mould trail samples sent to customer to confirm the quality. After quality confirmed by customer, then we can arranage to ship the moulds.

Screenshot, WeChat recognition QR code

WeChat account:+8613251068920

(Click WeChat to copy and add friends.)