+8613251068920

+8613251068920In some living area, people use water bucket (or called water pail) to transport water. Such as the area not have water supply system, people wash clothes beside river or stream, etc. So water pail have its market which can not be ignored. Taizhou Xiongshi Mould Co., Ltd accumulated strong technology in manufacturing water bucket moulds. Rich experince design team, advanced tooling machines, highly educated engineers and efficient management system.

Water Bucket Mould | Pail Mold part design.

There are some different ways to make the bucket design. 1. Customer provide 3D part design; 2. customer provide sample, making 3D part design according sample; 3. customer provide sample pictures and detail sizes, making the 3D part design according the pictures. There is defect on the thrid way, because making design according pictures some details will be different with the original sample. Below picture is customer's orignal sample picture.

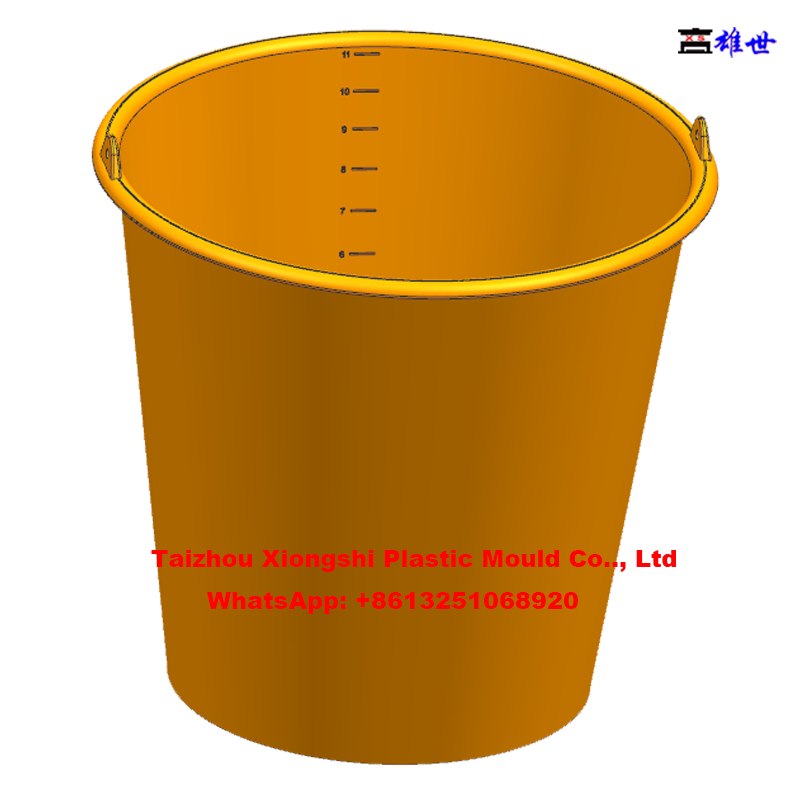

Water pail mould part 3D design pictures show:

Water pail mould part 3D design pictures show:

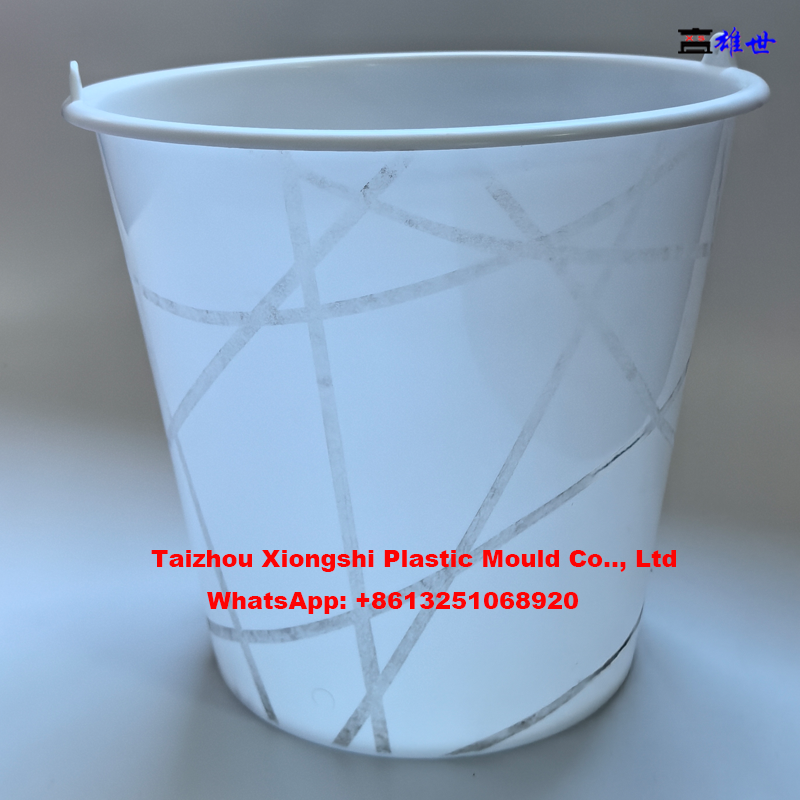

From above pictures we can see the 3D part design pictures almost same with original samples. But there are differences on the surface design and top edge design.

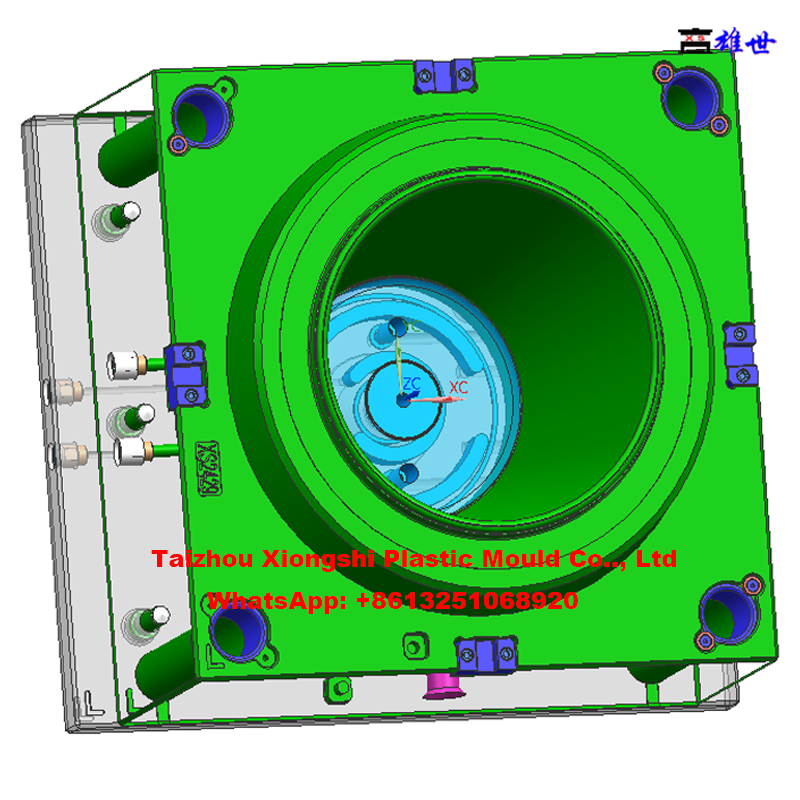

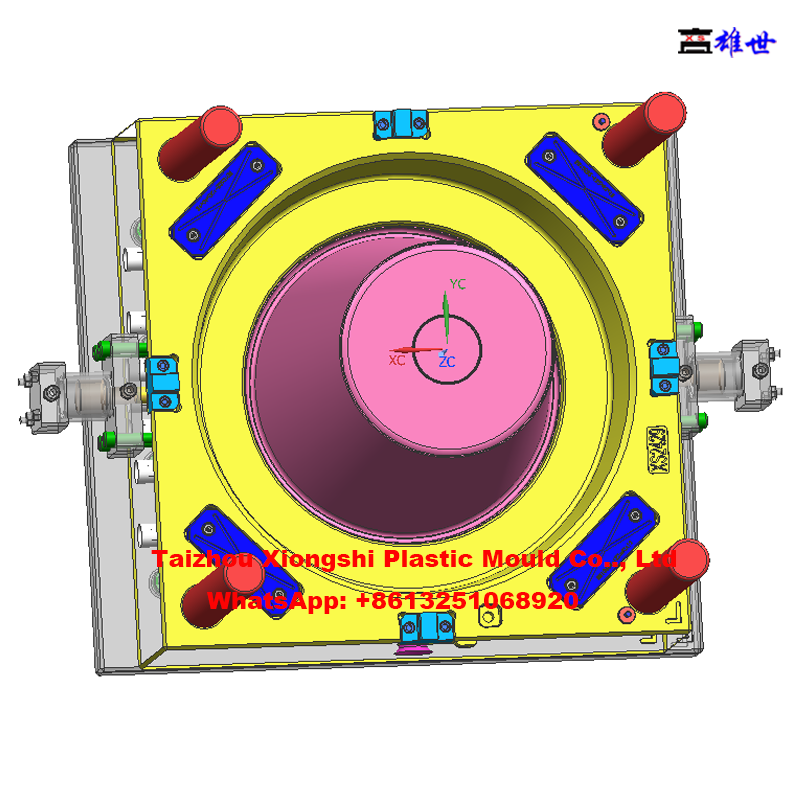

Water Bucket Mould | Pail Mold 3D design.

Water Bucket Mould | Pail Mold tooling process.

Mould Steel Cutting --> Rough CNC Milling Tooling --> Boring tooling --> Rough Lathe Tooling --> Drilling --> Deep Hole Drilling --> Precise Lathe Tooling --> Assembling --> Polish --> Mould Trail.

Water Bucket Mould | Pail Mold Trial.

Water bucket mould trail videos will be sent to customer to confirm the mould movement and quality. For some complex mould we will send the mould test prameters to customer for reference. Mould trail samples will be delivered to customer by FedEx or DHL to check the sizes and quality.

Water Bucket Mould | Pail Mold Trial Samples.

Water Bucket Mould | Pail Mold picture.

Screenshot, WeChat recognition QR code

WeChat account:+8613251068920

(Click WeChat to copy and add friends.)